Algae and Plant Oils to JP-8 and Navy Distillate Fuel (Florida, 2007-2011)

T2C-Energy CEO Devin Walker contributed to the development, design, and implementation of a catalytic hydrothermolysis project contracted by the US Air Force to produced over 100,000 gallons of jet fuel and diesel for the the US Air Force and Navy (allowed first 100% renewable jet fuel test flight by Air Force).

Enhanced Oil Recovery by Natural Gas and Nitrogen Injection (Elk Hills Petroleum Reserve, 2014-2015)

T2C-Energy EVP Timothy Roberge contributed to the development, design, and implementation of enhanced oil recovery by injecting and recycling more than 100 MMCFPD of a 75% N2/25% Natural Gas into an anticline reservoir. This compression expansion project netted an increase of 10,000 barrels of oil/day in the following year. This project was financed by California Resources Corporation.

Conversion of Landfill Gas to Liquid Fuel (Florida, 2016)

Conversion of Landfill Gas to Liquid Fuel (Florida, 2016)

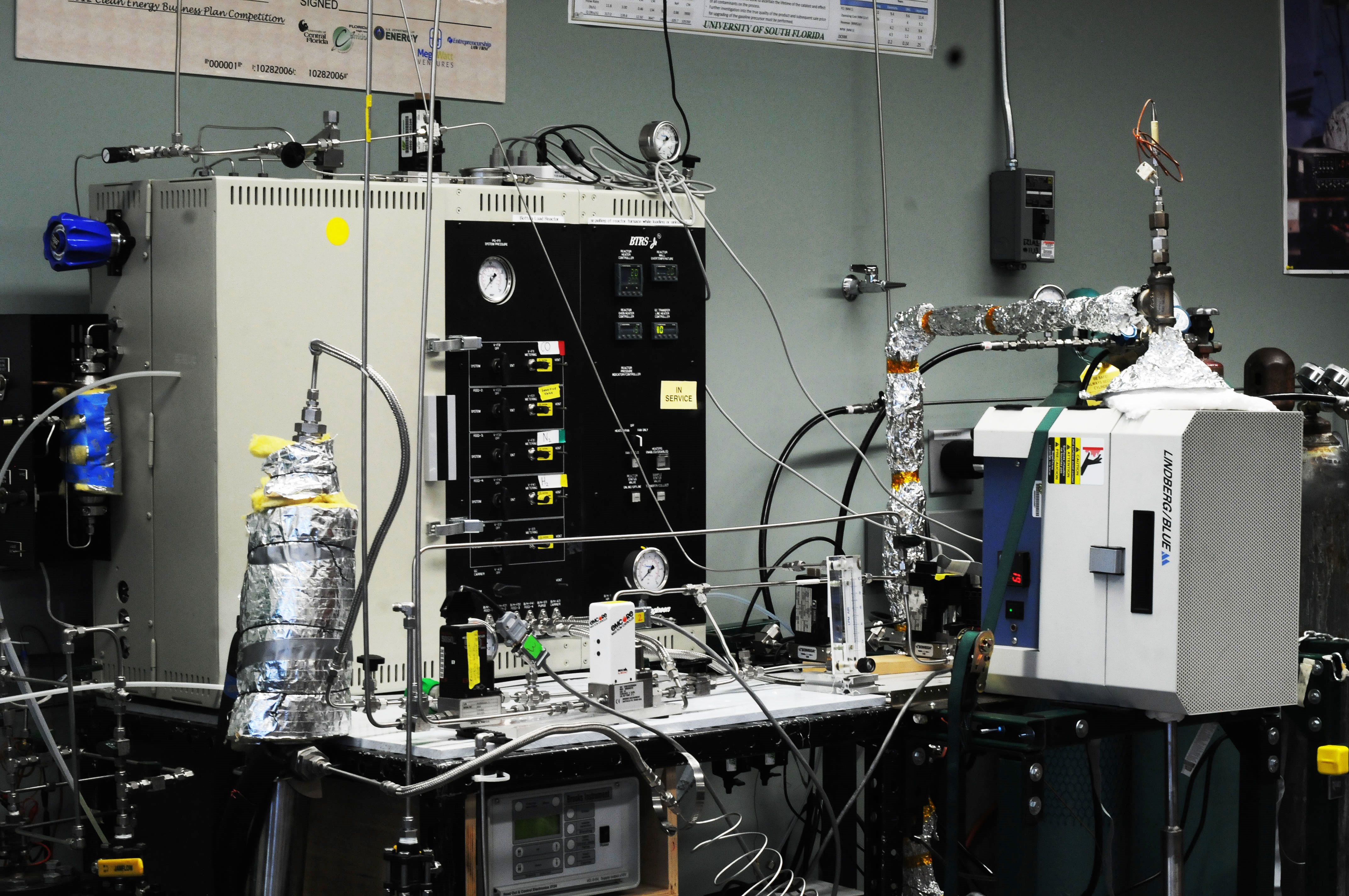

T2C-Energy proof of concept that landfill gas could be converted into a drop-in diesel fuel. T2C-Energy compressed raw landfill gas from Sarasota County Landfill for bench scale testing. T2C-Energy constructed and implemented a fully integrated bench system to convert raw landfill gas to renewable cellulosic diesel. A proprietary contaminant removal process was designed to remove all sulfur, siloxane, halogens, and ammonia from the raw biogas. The bench unit integrated a steam and air injection system, condensate removal system, tri-reforming reactor system, Fischer Tropsch reactor system, and product separation system. The results were groundbreaking in that raw landfill gas had been successfully converted into a drop-in diesel that passed ASTM D975 specifications. The bench scale system proved the the carbon present as carbon dioxide in the biogas could be incorporated into the backbone of the hydrocarbon fuel product.

Engineering and Construction Demonstration Unit (Florida/South Carolina 2017-2018)

Engineering and Construction Demonstration Unit (Florida/South Carolina 2017-2018)

From the bench scale results, data programming, engineering software simulation, and techno-economic analysis, T2C-Energy modeled and designed a portable demonstration unit to de-risk technology at the engineering scale and open a pathway for commercialization. The EPC bid for this contract was awarded to Xytel Corporation. The unit is a turn-key design, capable of converting 25 scfm of crude biogas into 52 gallons of renewable, drop-in diesel fuel. Both US Cleantech and the US Department of Energy financed this effort.

Cow Manure Anaerobic Digestion to Diesel Demonstration (Trenton FL - February-May, 2019)

T2C-Energy performed a 4 month demonstration with its mobile TRIFTS pilot unit at Alliance Dairies’ manure digester in spring of 2019. T2C-Energy commissioned and operated the plant with raw biogas derived from cow waste. The contaminant removal system proved the ability to reduce H2S concentrations from 5,000 ppm to less than 3ppm H2S. Funding for this operation was provided in part by our equity partner, US Cleantech and the US Department of Energy.

Landfill Gas to Diesel Demonstration (Brooksville FL - 2019)

Landfill Gas to Diesel Demonstration (Brooksville FL - 2019)

T2C-Energy installed its mobile TRIFTS demo unit at the Hernando County Municipal Solid Waste Facility T2C-Energy to produce approximately 1,000 gallons of diesel at a nameplate rate of 52 gallons/day. This proved the ability to produce renewable cellulosic diesel fuel from poor quality landfill gas with high carbon dioxide compositions. Funding for this operation was provided in part by our equity partner, US Cleantech and the US Department of Energy.

Long term Landfill Gas to Diesel Demonstration (Lecanto FL 2019-2020)

T2C-Energy partners with Citrus County Municipal Solid Waste Landfill to perform long term testing and prove process and catalyst longevity over seven months of continuous operation. The pilot was subjected to landfill conditions and proved the ability to efficiently convert raw biogas over industrial relevant time periods with no loss of catalyst activity. From this testing it's projected the TRIFTS process will have a 93% On-stream Factor at industrial scale.