Leveraging novel catalyst technologies, T2C-Energy developed and patented a process, we have trademarked TRIFTS®, by which biogas (or landfill gas) is converted to liquid fuels. The TRIFTS® process first converts the biogas to syngas (using a tri-reforming catalyst) and then produces liquid hydrocarbon fuels (using a Fischer-Tropsch Synthesis catalyst specifically tailored to produce large fractions of middle distillate fuel). In doing so, the technology is able to utilize both the methane and carbon dioxide portions of biogas maximizing the utilizable carbon an increasing conversion efficiencies by 84% over current state of art (biogas to RNG).

Leveraging novel catalyst technologies, T2C-Energy developed and patented a process, we have trademarked TRIFTS®, by which biogas (or landfill gas) is converted to liquid fuels. The TRIFTS® process first converts the biogas to syngas (using a tri-reforming catalyst) and then produces liquid hydrocarbon fuels (using a Fischer-Tropsch Synthesis catalyst specifically tailored to produce large fractions of middle distillate fuel). In doing so, the technology is able to utilize both the methane and carbon dioxide portions of biogas maximizing the utilizable carbon an increasing conversion efficiencies by 84% over current state of art (biogas to RNG).

From our process a renewable, high quality, liquid transportation fuel is produced resembling its petroleum derived counterparts. Existing fuel infrastructure can be utilized in the use, drop in ready, and transportation of the fuel. By using the true "green" fuel produced to power the the heavy trucking, aviation and marine industries, greenhouse gas emissions are not only reduced at the landfill or AD site but from the engine exhaust. The market for diesel is well established with the U.S. waste and agriculture sector making up 6.9% of the total diesel consumption (4.2 billion gallons of diesel annually) and equates to a $10.3 billion dollar expenditure in these industries alone. The environmental attribute credits, RIN credits through the EPA RFS policy, LCFS credits, and price of fuel relative to commercial diesel provide incentives to use this renewable diesel over commercial diesel fuel. A D7 RIN is produced in the distribution of the cellulosic diesel with over 70% GHG reduction in its from process to wheel.

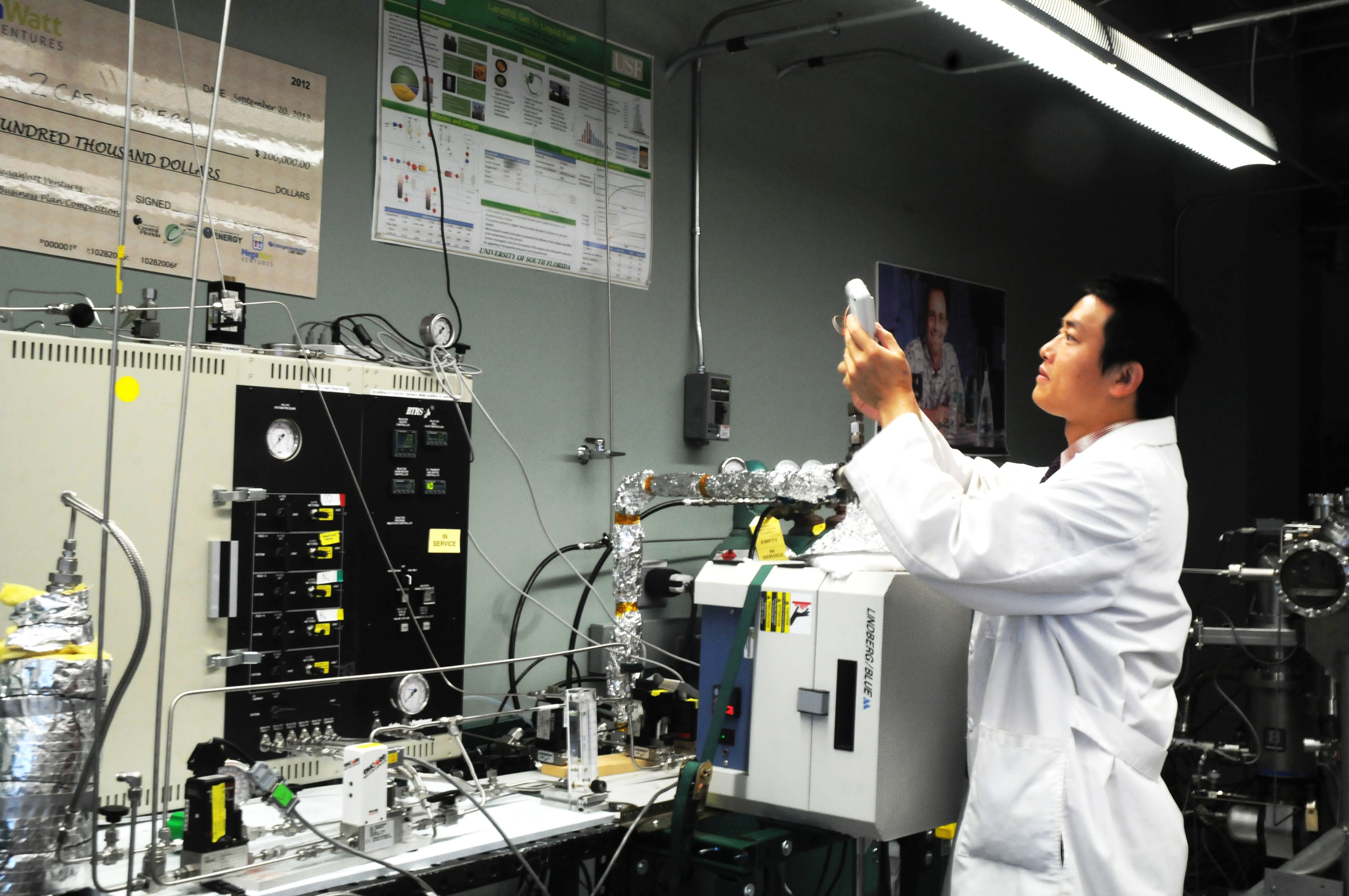

The innovation lies in synergistically combining two transformative catalyst technologies with the capability to produce transportation fuel from biogas more efficiently and cost effectively than any other existing technology thus converting an environmentally harmful waste gas into a high value/demand renewable liquid fuel. The process of reforming hydrocarbons is widely used in the oil and gas industry but only steam reforming and autothermal reforming (combination of sub-stoichiometric combustion and steam reforming) are done at the commercial level. In fact there are no commercial scale reactors that utilize a steam/carbon dioxide bi-reforming or tri-reforming to date. Furthermore T2C-Energy has developed the world’s first bench, pilot, and demo scale units processing biogas into syngas via tri-reforming. Our patented process is superior to current commercial technology as it describes a two stage process that utilizes a tri-reformer coupled to an FTS reactor (TRIFTS®) to produce liquid fuel with fewer reaction steps leading to significant CAPEX adn OPEX cost reductions brining Gas to Liquid Processing to current waste industry scales.

T2C-Energy’s process is revolutionary in that it utilizes both components of the biogas feed stream (CH4and CO2). Previous research by T2C-Energy led to the development of a patented FTS cobalt catalyst with an eggshell morphology. This work led to the design and synthesize of precisely tailored eggshell catalysts (loading the outer periphery of a silica particle with cobalt metal) that produces a highly selective product distribution, especially concentrated around the middle distillate region. Current FTS energy projects are plagued by high capital and operational costs that make small-scale energy projects uneconomical and unattractive. Much of the costs associated with FTS are due to the extensive post treatments (Ex. hydrotreatment, hydrocracking, and distillation) and therefore T2C-Energy’s avoidance of these costly post treatments drastically reduce overall costs. T2C-Energy technology uses patented catalyst with vastly improved efficiencies to conventional catalyst leading to superior process design, efficient use of heat streams, and balancing of exothermic reactions to drive endothermic reactions, thus lowering costs significantly. We can therefore achieve an economy of scale to operate GTL plants at existing AD and landfill facilities. Our design and economic models show that T2C-Energy can convert the biogas to liquids in a profitable manner without government subsidies adding an additional layer of economic stability.

Present day technologies are only able to utilize the methane component of biogas with carbon dioxide simply passing through the process (CO2does not combust). This CO2represents over 60% by wt. of the biogas. TRIFTS® utilizes both major components of biogas (CH4and CO2). Biogas processed into high-energy diesel fuel can easily be stored, transported, and used at the convenience of the user. This is a major advantage over biogas to electricity or RNG technologies.This provides a pathway for the waste industry to become truly 100% sustainable and self sufficient with no outside fossil fuel demands. T2C-Energy’s technology produces a renewable drop-in fuel in the middle distillate boiling range we have termed TRIFTS® fuel. The renewable fuel produced resembles its petroleum derived counterpart both physically and chemically so it can be utilized as a drop-in fuel with no engine modification requirements or blending requirements and avoids some of the negative environmental and health impacts typically associated with fossil fuels. This provides for tremendous cost savings as existing fuel infrastructure can be used in the use and distribution of the renewable fuel. The TRIFTS fuel is not only 100% waste derived renewable diesel that can replace typical fossil fuel derived diesel, it is also cleaner burning. TRIFTS fuel has >0.3% aromatics, hence its clear color compared to commercial diesel. The low aromatic content leads to a more complete combustion cycle meaning significantly less soot and particulate formation. Additionally, there is 0ppm sulfur compared to commercial ultra-low sulfur diesel of 15ppm therefore no SOx emissions. The TRIFTS fuel reduces NOx emissions and has an excellent Cetane number making it a good candidate to decrease criteria pollutant emissions and improve key fuel properties as a blend-stock to commercial fuels. The TRIFTS fuel can be utilized as a 100% drop-in replacement to fossil fuel derived diesel or blended at any ratio with commercial fuels. It is important to note that our product distribution can easily be tuned by controlling the eggshell thickness and process conditions of our Fischer-Tropsch Synthesis (FTS) catalyst. We therefore have the flexibility to also produce renewable drop-in jet fuel for the aviation industry and marine/navy distillate fuels.